The FasTrac EP1500 Epoxy Pump system is the next generation in two-component meter-mix systems. Why? The FasTrac EP1500 is a self-contained unit that is simple to operate, has few moving parts and requires no supplemental transfer pumps or air compressor. That means the EP1500 is the lowest maintenance epoxy pump system currently available.

Mon - Fri 8:00AM - 5:00PM Central

1150 SE Hamblen Rd, Lee's Summit, MO 64081

FasTrac EP1500 Portable Epoxy Pump System

The Next Generation in Portable Pump Systems

Benefits of the FasTrac EP1500 Epoxy Polymer Pump System

The FasTrac EP1500 monitors and maintains mix ratio automatically, monitors and displays pressure and flow rate and displays and records the total quantity of individual and combined components. The EP1500 is also capable of up to 15 gallons per minute output; more than any other pump system currently on the market! The FasTrac EP1500 pumps are also reversible so it can be used to refill totes or tanks. That means no messy disconnecting of hoses to replace totes, no slow, manual refilling, and no additional pumps necessary! Clean and simple!

Your All-In-One Polymer Pump System

The EP1500 comes equipped with an 8 foot boom and 16 feet of output hose which makes it capable of dispensing material over a 32+ foot wide area. The mix portion of the system provides a far greater mix quality and consistency than conventional systems. It also uses permanent, reusable static mixer elements which saves the contractor money. The built-in generator system on the FasTrac EP1500 is also capable of powering tote/tank heaters as well as other equipment and lighting.

Read about our Epoxy Pump’s first project here.

Features

- Capable of up to 15 Gallons Per Minute Total Output

- Portable System

- Simple Operation

- Self-Contained (with Optional Built In Generator)

- Fully Enclosed

- No Transfer Pumps or Air Compressors Required

- Full Electric Operation

- Built In Generator Can Also Be Used to Power Tank/Tote Heaters

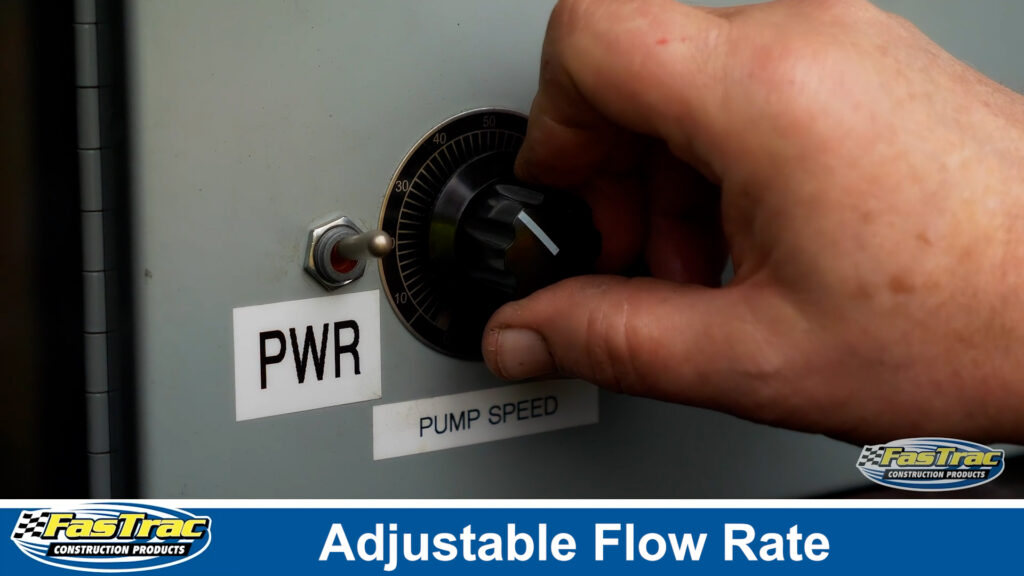

- Adjustable Flow Rate

- Maintains Mix Ratio Automatically

- Monitors and Displays Flow Rates for Each Component

- Displays Total Gallons for Each Component and Combined Total

- Automatic Over Pressure Shutdown

- Pumps are Fully Reversible so They Can Be Used to Fill/Refill Totes or Tanks

Applications

- Bridge Deck Epoxy Overlays

- High Friction Surface Treatment

- Parking Deck Overlays

- Lane Demarcation

- Highway Repair

- Floor Coatings

- Waterproofing

- Concrete Restoration

Tech Specs

- Power Requirements (w/o Built-In Generator): 4 hp (3000 w)

- Built-In Generator Power Output: 6500 w

- Two Built-In 20 Amp 120v Outlets for Powering Lights, Heaters, Equipment

If you are looking for a better alternative to the pump systems currently available, the FasTrac EP1500 is the right choice!

Spoiler alert! The EP2000 is on the way!

Ready to enhance your workflow with FasTrac?

Contact us today and learn how the EP1500 Portable Epoxy Pump System can increase your job site efficiency, improve quality and save you money!

While you're here... These products are perfectly matched to the EP1500!

Check out FasTrac’s high-performance Epoxy products like FasTrac CE 330 Epoxy Binder and FasTrac CE 335 Bridge Sealer.

About FasTrac Construction Products

With more than 30 years experience in developing and manufacturing cutting edge products, FasTrac Construction Products are known for performance and consistency. When combined with our commitment to excellent customer service you have a winning combination that brings value to the construction industry.

Like our YouTube Channel for product reviews and project highlights, and don’t forget to follow us on Facebook!

Do you have any questions?

Don't hesitate to contact us. We are always here to help take your business to the next level.

Contact Us