FasTrac CE815 Epoxy Grout is a three-component, 100% solids, high performance, epoxy machine grout. It is characterized by low dust, high bearing area, low exotherm, negligible shrinkage and creep, fast cure and excellent flowability.

Mon - Fri 8:00AM - 5:00PM Central

1150 SE Hamblen Rd, Lee's Summit, MO 64081

FasTrac CE815 EPOXY GROUT

HIGH PERFORMANCE EPOXY GROUT

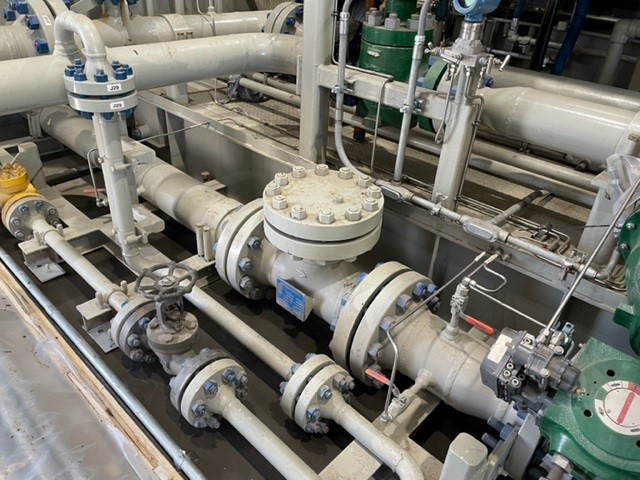

FasTrac CE815 Epoxy Grout is ideal for high stress applications such as wind turbines, gas transmission, refining, chemical processing, pulp and paper, crane rail, marine and other machine base plate grouting. New equipment installations or re-grouting applications subject to chemical attack and extreme vibration are ideal for CE815 Epoxy Grout. CE815 can also be used as an anchoring adhesive.

Features

- Made in America

- High impact resistance, high early strength, high effective bearing area and excellent flowability.

- Low exotherm cure for deep pour capability

- High oil and chemical resistance

- Precision grouting with negligible shrinkage and creep

- Pre-measured units

- Easy soap and water clean up

CE815 vs OTHER EPOXY GROUTS

Energy Tech Systems based out of Exton, PA, is the North Eastern US’s leading epoxy grout supplier. Founded in 1992, Energy Tech continues to be a primary source for industrial machinery grouts, natural gas engine & compressor parts and epoxy pipe supports.

Last month, Energy Tech conducted an Epoxy Grout Shootout. They tested some of the top epoxy grouts on the market, including our very own FasTrac CE815 Epoxy Grout. Check out the video below!

Would you like to know more about the test results? Get the full study here.

CE815 vs Escoweld

Energy Tech Systems followed up their first Epoxy Grout Shootout with Epoxy Grout Shootout 2.0. Epoxy grouts tested were Escoweld 7505E/7530 and FasTrac CE815.

Epoxy grout tests included ASTM 1339 flow box test, ASTM C579 Method B, Load Rate II, and ASTM D2471 Peak Exotherm. Check out the video below!

Would you like to know more about the test results? Get the full study here.

Packaging

2.0 cu. ft.

Component A – (1) premeasured 5-gallon pail

Component B – (1) 1-gallon jug

Component C – (4) 55-lb bags aggregate

Packaging

0.5 cu. ft.

Component A – (1) 1-gallon jug

Component B – (1) 1-quart jug

Component C – (1) 55-lb bag aggregate

Shelf Life

2 years in original unopened containers

Storage

Store at 40F-95F (5C-35C)

Application Temperature Range

Condition material to 65⁰F – 95⁰F (18⁰C – 35⁰C) before using.

Do you have any questions?

If you’ve got questions, we’ve got answers. We take pride in our customer service, and we look forward to your call or email.

Contact Us